Browning A5 Friction Ring Setup

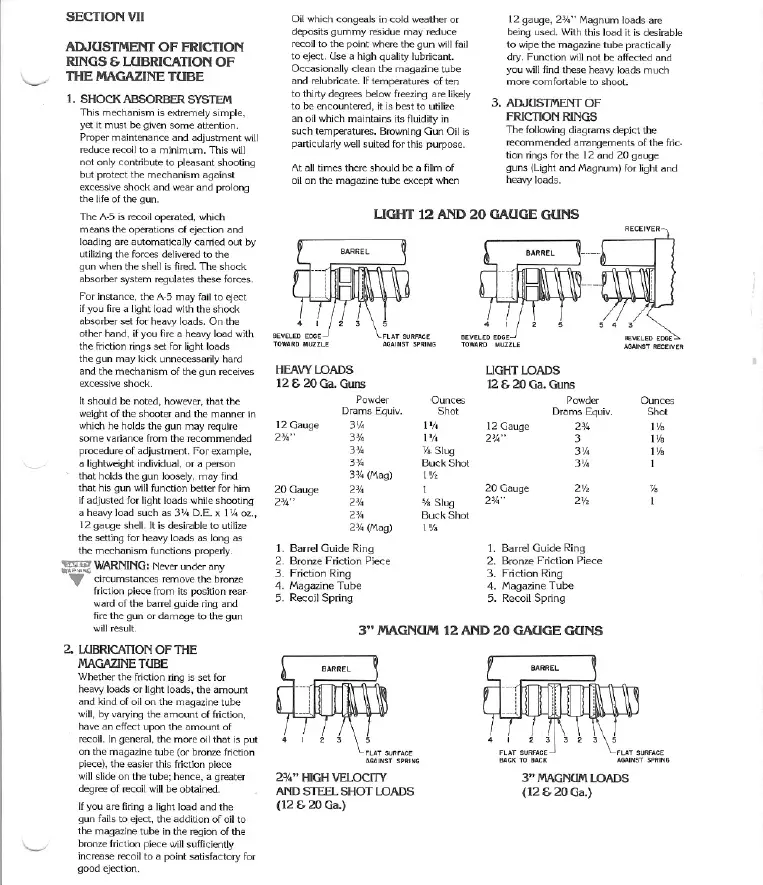

Light 12 20 and standard a5 s 12 16 20 come with only one 1 bronze friction ring and one 1 flat surfaced beveled surface friction ring.

Browning a5 friction ring setup. The instructions in an old browning booklet which was from an old browning a 5 12 gauge which i no longer have says that if the friction rings is installed on the receiver end of the spring i e. Just a short video on how to setup the friction and bronze pieces on a browning auto 5 magnum twelve. Loads i get from walmart the 28 barrel does best in the low drag setup with the drag ring below the recoil spring against the receiver and an older slightly compressed recoil spring. Friction ring adjustment for auto 5 light 12 sweet 16 and 20 gauge models.

Let s talk a 5 light twelve. The beveled side of the bronze friction piece mates with the beveled portion of the barrel ring always. Last updated on mon 10 aug 2020 browning auto 5 light 12 the single difference from the arrangement given for heavy loads is a change in the position of the friction ring. The 24 does best with a new recoil spring and the friction ring against the receiver.

Settings for shooting 2 3 4 inch magnum steel shot and high velocity loads the following instructions are only for 2 3 4 inch 12 sweet 16 and 20 gauge models not the 3 magnum 12 gauge or the 3 magnum 20 gauge semi automatic. Click on a term to search for related topics. Browning a5 friction ring set up browning a5 light 20 gas ring assembly browning a5 ring diagram browning auto 5 friction ring diagram friction ring for a browning auto 5 friction ring setting auto 5. For light loads this friction ring is taken off and placed at the extreme rear end of the magazine tube between the rear end of the recoil spring and the receiver with the beveled edge turned toward the receiver.

It is simple enough. The flat side of the bevel washer always resides against the recoil spring. The 20 barrel wants a new spring with the friction piece in the high drag. On both light models and standard models the bronze friction ring and flat beveled ring are set up forward of the spring against the concave of the barrel for heavy loads.